Sparkoz, a specialist in autonomous cleaning service robots,has deployed its technology in over 100 cities worldwide.With the increasing cost of cleaning,our robots are being utilized in diverse scenarios,and most customers prioritize reducing operational costs.In this article,we share our experiences,observed benefits,and encountered challenges in deploying these robots globally.

1. Automated Features Reduce Manual Intervention

Industrial robot vacuum cleaners are equipped with features such as automatic charging, self-emptying cassettes, and self-cleaning bases, reducing the need for manual maintenance.

At Sparkoz, we offer a selection of charging docks and workstations for each of our cleaning robots. These charging docks ensure stable, efficient recharging, while the workstation help fills the water tank and manages wastewater disposal, enabling continuous operation.

Watch the video to see how TN70 drain waste water with worksation: https://youtu.be/1qyfFSuO2tc?si=VAwe5JB0m_nZYtIA

AI-driven monitoring systems analyze sensor data to predict maintenance needs before failures occur. These automation capabilities minimize machine downtime and eliminate manual steps such as charging and water replacement—cutting labor costs and lowering maintenance costs up to 30%.

2. AI Navigation and Obstacle Avoidance Reduce Equipment Damage

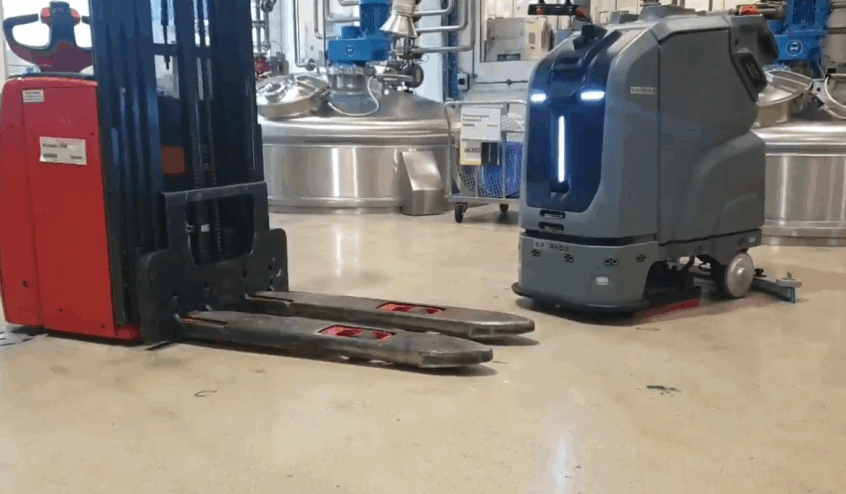

Industrial cleaning robots leverage advanced AI algorithms like SLAM for real-time positioning and CNNs for visual obstacle recognition and classification. With enhanced vision and multi-sensor fusion,these robots intelligently navigate complex environments,avoiding obstacles such as power cords,forklifts,and pedestrians.

Sparkoz TN70 avoiding forklift trucks

Compared to traditional models, these technologies reduce collision-related failures, reduce the failure rate by up to 40%, extend equipment life, and cut average annual maintenance costs by approximately 25%.

3. Modular Design Simplifies Component Replacement

Modern commercial cleaning robots feature modular designs that integrate sweeping, washing, vacuuming, and squeegeeing. When a failure occurs, only the relevant module needs to be replaced rather than the entire machine.

Sparkoz robots, for instance, support quick disassembly and replacement of brushes and cleaning assemblies, enabling different cleaning modes. This design cuts maintenance time by 50% and reduces spare parts costs by 20%.

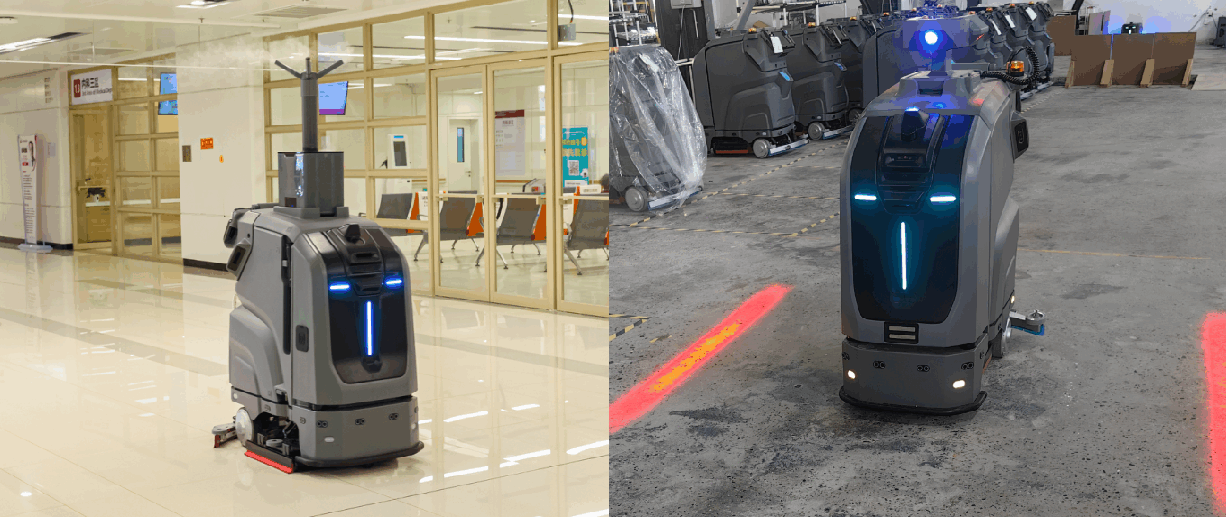

Modular design also allows easy function expansion. Sparkoz offers a safety spotlight module for warehouse environments to enhance forklift safety, which installed in the upper part of the robot. In the same position, it is also possible to adapt an disinfection fogger module.

TN70 with disinfection fogger module and safety spotlight module

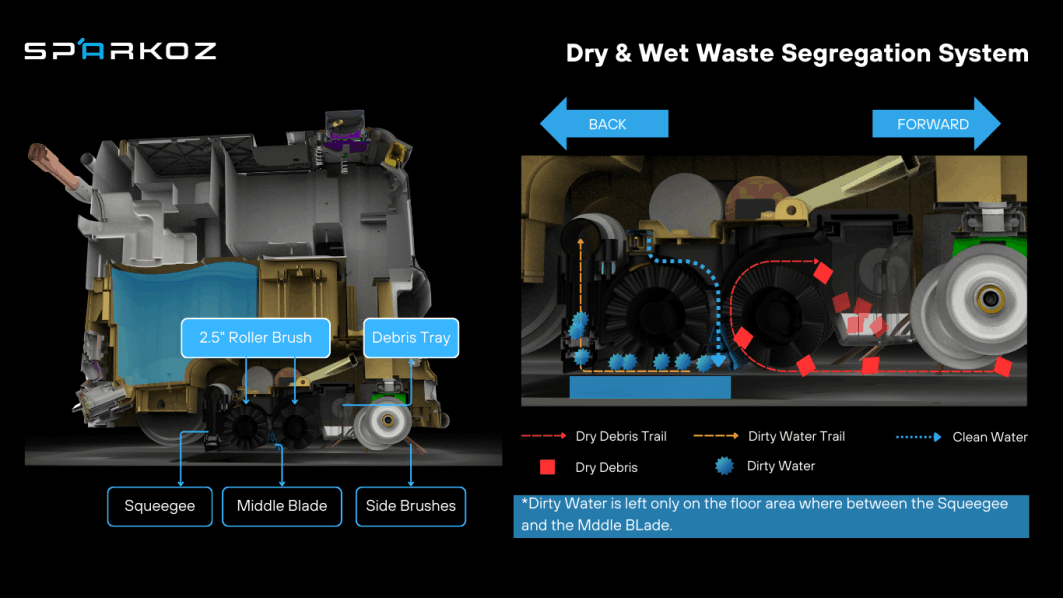

The robots effectively separate and collect waste: dry debris is swept into a dust container while wet waste is immediately vacuumed. The Sparkoz TN10 , industrial robot vacuum cleaners, ensures efficient waste collection while preventing wet smearing on floors.

This system prevents internal clogging, minimizes maintenance requirements, and reduces downtime. It also avoids performance issues caused by the accumulation of mixed waste, ensuring greater cleaning stability and effectiveness.

TN10 dry & wet waste segregation system

5. Efficient Battery Management and Low Power Consumption

Industrial robots vacuum cleaners are powered by high-density lithium batteries managed by intelligent algorithms. They can clean over 2,000 square meters per charge while reducing charging frequency.

Optimized path planning further lowers energy usage. Battery lifespan can exceed five years, cutting annual battery replacement costs by up to 35%.

6. Cloud-Based Scheduling Improves Cleaning Efficiency

Multi-robot collaboration is enabled by cloud-based scheduling, which prevents task overlap and inefficient cleaning routes.

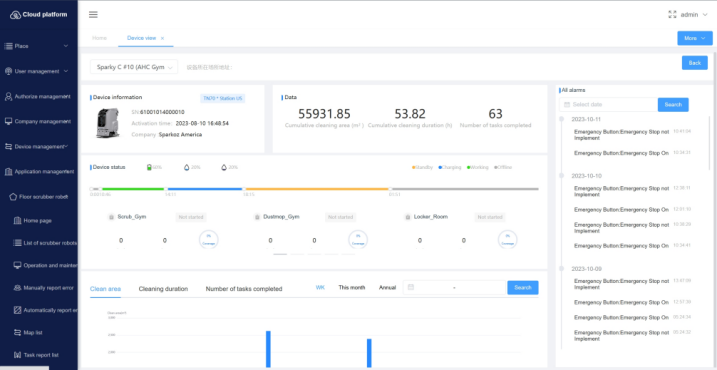

Sparkoz robots support clustered operations, improving cleaning efficiency by 40% and reducing equipment wear by 30%. Centralized management also allows for remote monitoring, cutting the need for on-site personnel.

Sparkoz cloud platform

7. Predictive Maintenance and Remote Diagnostics

Sensors and real-time analytics enable manufacturers to monitor system health and predict failures before they occur. Sparkoz's cloud platform (shown above) provides early warnings for motor wear or brush clogs, reducing downtime-related losses.

Preventive maintenance can reduce unexpected repair costs by up to 40%. In addition, remote firmware updates eliminate many on-site service needs.

Ready to Try It Yourself?

Our experience with industrial robot vacuum cleaners has demonstrated that,despite the initial high costs,investing in robotics can lead to substantial savings in labor and maintenance over time. However, industrial robot vacuum cleaners don't work best in all environments, so if you're considering investing in industrial cleaning robots, carefully assess your needs and circumstances, and it may be helpful to consult with an industry expert or independent professional.