You can now see warehouses changing quickly as industrial cleaning robots do hard cleaning work. These robots, like the Sparkoz TN70-PRO, clean all day and night. They can fit into any space. More people are using these robots, as you can see below:

| Robot Type | Growth Metric / Statistic | Timeframe |

| Mobile Robots | Expected CAGR of 20.5% | Through 2030 |

| AGVs | Adoption growing at 13% CAGR | Recent years |

| Amazon Robots | Over 750,000 deployed | Current |

With these robots, you get:

● Cleaner and safer floors

● Lower labor costs

● Results that are always good

● Better safety for workers

Robots like the TN70-PRO help keep your warehouse very clean. They help your team and save you money.

Warehouse Cleaning Challenges

Labor Shortages

It is hard to find enough people to clean warehouses. Many warehouses do not have enough workers for cleaning. When there are not enough staff, cleaning gets skipped or delayed. This makes the warehouse messy and crowded. Surveys show these problems hurt how well people work and how they feel about their jobs. Here are some main problems managers see:

1.Messy warehouses make it hard for workers to do their jobs.

2.When things are not organized, people make more mistakes and work longer.

3.Workers spend extra time looking for things in messy places.

4.Bad organization can make it easier for things to get stolen.

5.Machines break down faster when dirt and clutter pile up.

6.More slips and trips happen, which can hurt people.

7.A dirty warehouse can make your company look bad.

You need to clean often to stop these problems,but not having enough workers makes it hard.

Inconsistent Results

Manual cleaning does not always give the same results. Some workers clean well, but others miss spots. This can make the warehouse less safe and lower quality. Different ways of cleaning have good and bad points. Look at this table:

| Method | Advantages | Disadvantages |

| Performance observations | Direct feedback, simple, inexpensive | Subjective, labor-intensive, inconsistent standards |

| Visual assessment | Easy, immediate feedback | Subjective, does not show true cleanliness |

| Fluorescent markers | Objective, quick feedback | Labor-intensive, time-consuming, needs frequent changes |

| ATP bioluminescence | Quick, objective, immediate | Expensive, variable sensitivity, lacks clear standards |

| Environmental cultures | Sensitive, direct measurement | Expensive, slow, needs lab resources, no clear benchmarks |

Manual cleaning depends on what each person thinks is clean. This makes it hard to get the same results every day.

Safety Concerns

Safety is very important in a warehouse. Slips, trips, and falls happen a lot when floors are dirty or full of stuff. OSHA says about 25% of warehouse claims are from these accidents. You can stop many injuries by keeping floors clean and dry. Clean up spills fast and keep walkways open. Accidents often happen because of:

● Dust and dirt on the floor

● Spilled liquids or oil

● Aisles that are messy or blocked

If cleaning is late,accidents are more likely. This can even close the warehouse or cause fines. Cleaning often helps keep workers safe and follow safety rules.

Industrial Cleaning Robots in Action

Automation and Navigation

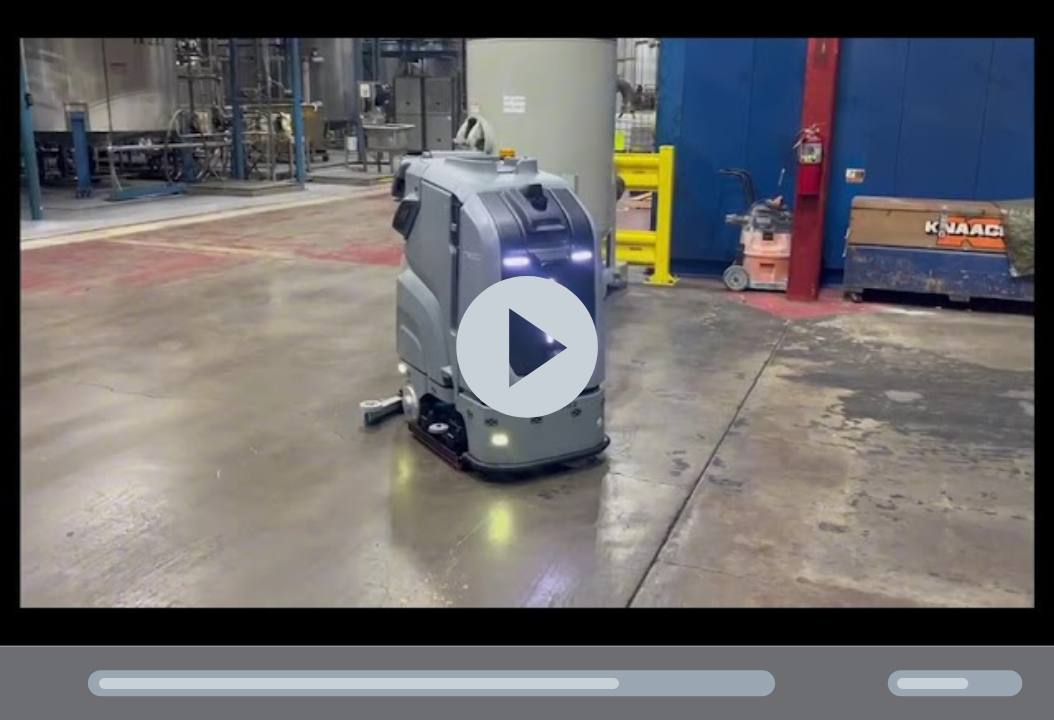

Industrial cleaning robots make warehouse cleaning much easier. These robots, like the Sparkoz TN70-PRO, do not need much help from people. They use smart navigation to move by themselves. Sensors and cameras help them see and make maps. The robot finds the best way to clean every part of the warehouse.

The TN70-PRO uses AI-powered navigation, LiDAR, and 360° panoramic cameras. These tools help it see all around, even in dark places or when things are in the way. If something blocks its path, the robot can change direction. It also uses SLAM technology. This lets the robot update its map if your warehouse changes. You can also set cleaning patterns with an easy-to-use interface.

Tip: These features let the robot keep cleaning, even if you move shelves or change the layout. The robot quickly adapts and does not stop working.

See the demo: https://youtu.be/eGTWSyz8yjc

Consistent Performance

You want your warehouse to look clean every day. Industrial cleaning robots help you reach this goal. They follow the same steps each time, so cleaning is always the same. The TN70-PRO keeps track of where it has cleaned, how often, and how much space it covers. You can check these reports to see proof of the work.

Here are some ways these robots keep your warehouse clean and consistent:

● They make cleaning better, which is important for managers.

● They clean the same way every time, so nothing gets missed.

● They track and report every job, so you can check the results.

● They work well even if you have fewer workers.

You do not have to guess if the warehouse is clean. The robot gives you data and proof, so you know your warehouse meets your standards every time.

Safety Features

Safety is very important in every warehouse. Industrial cleaning robots have many safety features to protect people and equipment. The Sparkoz TN70-PRO has earned important safety certifications, like FCC, CE, and TUV. These show the robot meets strict safety rules in the United States, Europe, and other places.

Here is a table showing what some of these certifications mean:

| Certification | What It Means |

| FCC | Meets US rules for electronic safety |

| CE | Follows European safety and quality standards |

| TUV | Passes German safety checks |

The TN70-PRO uses sensory redundancy, which means it has extra sensors to help avoid accidents. If something unexpected happens, the robot can stop or change direction right away. You can trust the robot to work safely around people and machines.

Note: Picking a robot with these certifications helps you follow safety rules and avoid problems during inspections.

Technologies Behind Industrial Cleaning Robots

AI and Sensors

Industrial cleaning robots use new AI and sensor technology. These robots use machine learning to change how they clean. They look at real-time data and learn from each job. Over time, they get better at cleaning. The robots have sensors like LiDAR, ultrasonic sensors, and cameras. These sensors help the robot see what is around it. The robot can avoid things in its way and move safely. It works well even when the warehouse is busy.

Here is a table that shows how these technologies work together:

| Technological Advancement | Description | Impact on Operation |

| AI and Machine Learning | Robots learn and change cleaning patterns using real-time data. | Makes cleaning paths and schedules better. |

| Advanced Sensors (LiDAR, Cameras) | Give 360-degree maps and find obstacles or changes in the space. | Helps the robot move and clean safely and correctly. |

| SLAM and Machine Vision | Make real-time maps and plan new routes. | Lets robots work in places that change often. |

These features let cleaning robots work alone and help your warehouse run better.

IoT Integration

IoT integration makes cleaning robots even smarter. You can watch and control the robots from far away. This lets you see cleaning progress and fix problems quickly. IoT sensors collect data about the warehouse and how the robot works. AI uses this data to make cleaning plans better.

● You get updates and alerts right away.

● Watching robots from afar helps you find problems early.

● IoT helps keep robots working well and without trouble.

With IoT, your warehouse stays clean and safe with less work from you.

Smart Mapping

Smart mapping uses SLAM, LiDAR, and AI sensors to make good maps of your warehouse. The robot finds things like machines or people and changes its path. This helps the robot clean more space in less time.

● The robot picks the best cleaning routes.

● Central systems watch cleaning and make future routes better.

● You have less downtime and more cleaning done.

Smart mapping lets robots clean all the time with little help. Your warehouse stays clean, and work goes smoothly.

Benefits for Warehouse Management

Efficiency Gains

Industrial cleaning robots help warehouses work better. These robots clean the floors, so workers can do other jobs. The floors stay clean all day and night. You do not have to worry about dirty spots or missed cleaning. Robots like the Sparkoz TN70-PRO use smart navigation. They clean every area, even if the warehouse changes. This keeps cleaning standards high and helps keep workers safe. Many warehouses say robots make the space cleaner and safer with less work from people.

Tip:Using robots for cleaning lowers the chance of accidents. Clean floors mean fewer slips and falls.

Cost Savings

Robotic cleaning helps you save money in many ways. You need fewer workers for cleaning, so labor costs go down. Robots do not take breaks, so you do not pay for overtime. You also spend less on training and watching workers. Warehouses with robots often get fewer OSHA fines. Robots help keep the warehouse safe and clean. For example, a chemical plant in Idaho saved 35% after using robots. Robots also help stop equipment from breaking and lower fire risks by cleaning up dust.

| Benefit | Impact |

| Lower labor costs | Fewer staff needed for cleaning |

| Fewer OSHA fines | Better safety and compliance |

| Less downtime | Fewer accidents and equipment failures |

| Reduced training costs | Less need for supervision |

Employee Morale

Industrial cleaning robots help workers feel less stressed. Robots do the boring and hard jobs. Workers can do more interesting tasks. This makes people feel important and keeps them happy. Staff can learn how to use and manage robots, which gives them new skills. Many workers like being part of a company that uses new technology. They feel proud to work in a safe and clean place. When workers do more valuable jobs, they stay interested and want to do well.

-Robots do the same jobs over and over, so work is more fun.

-Learning new technology makes workers feel special.

-Workers can do jobs that need people, not robots.

-A clean and safe warehouse makes everyone feel proud and work together.

Comparing Robots and Traditional Cleaning

Productivity

You want your warehouse to run smoothly every day. Robots help you reach this goal by working without breaks or sick days. They clean large areas quickly and do not get tired. You can set them to clean at night or during slow hours. This means your floors stay clean all the time. Workers do not have to stop their main jobs to sweep or mop. You get more work done in less time.

Traditional cleaning depends on people. Workers may miss spots or forget to clean certain areas. Sometimes, cleaning takes longer because workers need breaks. Robots follow the same path every time, so you get the same clean results each day.

Tip: Using robots for cleaning helps you keep your warehouse ready for work at any hour.

Cost Analysis

You want to save money and get the best value for your cleaning budget. Robots can help you do this. Many warehouses see big savings after switching to robotic cleaning. You spend less on labor, training, and overtime. Robots also help you avoid fines by keeping your warehouse safe and clean.

Here is a table that shows how robots compare to traditional cleaning:

| Metric | Warehouses with Robots | Traditional Cleaning Methods |

| Efficiency Gain | 40% | N/A |

| Payback Period | 6 to 12 months | N/A |

| Cost Savings on Cleaning | 30% to 40% | Baseline |

| ROI (Return on Investment) | Strong ROI | Baseline |

You can see that robots pay for themselves in less than a year. You also get more value from your cleaning budget.

Human-Robot Collaboration

Robots and people work best when they work together. In many warehouses, robots handle the hard and boring jobs like floor scrubbing. This lets your workers focus on important tasks, such as helping customers or checking inventory. For example, a large grocery chain used over 40 robots to clean millions of square meters. Workers saved time and energy, and customers noticed cleaner stores.

You can help your team learn new skills by offering training programs. Some companies, like Amazon, have special classes to teach workers how to use and fix robots. These programs help workers move into better jobs and feel more confident.When people and robots work together, you get safer, cleaner, and more efficient warehouses.

Note: Training your team to work with robots helps everyone succeed and keeps your warehouse running smoothly.

Future Trends

Ongoing Innovations

Industrial cleaning robots are changing fast. The market for robotic floor scrubbers is growing quickly. Experts think it will be worth over $575 million by 2032. This is because robots are getting smarter with sensors and AI. These robots plan the best cleaning paths on their own. They need less help from people and work better.

Some robots now use cloud software. You can see cleaning progress right away and make good choices. New robots use machine learning to get better at cleaning. They learn from each job and improve their routes. Some robots can clean themselves and empty their own bins. In hospitals, robots use UV light to kill germs and keep things safe.

The Sparkoz TN70-PRO and other robots will keep improving. Future robots will have better sensors and smarter AI. They will handle harder warehouse layouts. You will get more ways to customize and save energy. These changes help you keep your warehouse clean and safe while saving money.

Tip: Look for robots that work with smart building systems. They can change cleaning plans if your warehouse gets busy or the air changes.

Integration and Maintenance

You can get ready for new robot technology by following some easy steps. Start with a good maintenance plan. Check your robots every day, month, and year. Look at batteries, sensors, and update the software. Clean the robots and make sure they work right.

Teach your team how to use and care for the robots. Only let trained workers use them. Use software to track when to check and fix robots. This helps stop problems and keeps robots working well.

Pick robots with automatic docking and self-refilling. These features save time and cut down on manual work. Put up safety barriers and warning signs to protect people and machines. If you need extra clean spaces, choose robots with special tools for disinfection.

More robots will connect with IoT systems soon. These robots get real-time data and change cleaning plans as needed. The Sparkoz TN70-PRO will likely get more smart features. This will make it easier to manage cleaning and keep your warehouse ready for the future.

You can see how industrial cleaning robots change warehouse management. These robots work all night and do not need breaks. You get clean floors every day. Your team stays safe because robots handle risky jobs. Costs go down as robots clean large spaces without extra pay.

● Robots clean with the same quality every time.

● They free your workers for important tasks.

● You lower risks and save money.

Consider the Sparkoz TN70-PRO if you want a smarter, safer, and more efficient warehouse.

FAQ

How do industrial cleaning robots like the Sparkoz TN70-PRO avoid obstacles?

The robot uses sensors, cameras, and smart mapping. It can see objects and people. When it finds something in its way, it changes direction. You do not need to worry about accidents.

Can you control the cleaning schedule for these robots?

Yes, you can set cleaning times using an app or control panel. The robot follows your schedule. You can change the plan anytime. This helps you keep your warehouse clean without extra effort.

Are industrial cleaning robots safe to use around workers?

The Sparkoz TN70-PRO has safety certifications like FCC, CE, and TUV. It uses extra sensors to stop or turn if someone gets close. You can trust it to work safely near your team.

What maintenance do these robots need?

You should check the robot's brushes, sensors, and battery often. Clean the robot and update its software when needed. Most robots show alerts when they need care. This keeps them working well every day.