The future of facility management is no longer a distant concept; it's already in action, gliding quietly through the aisles of warehouses, terminals of airports, and hallways of hospitals. For any manager overseeing a large commercial space, the challenges are persistent: high labor costs, inconsistent cleaning quality, and the constant risk of slip-and-fall accidents. The solution that is rapidly moving from a luxury to a necessity is the autonomous floor scrubber. These machines represent the practical, intelligent, and efficient future of commercial cleaning, and they are already proving their worth in the field.

This technology has evolved far beyond the simple robotic vacuums of the past. Today's industrial-grade autonomous scrubbers are sophisticated platforms designed for one purpose: to deliver a verifiable, high-level clean for large-scale environments with minimal human intervention.

How Autonomous Scrubbers Navigate the Real World

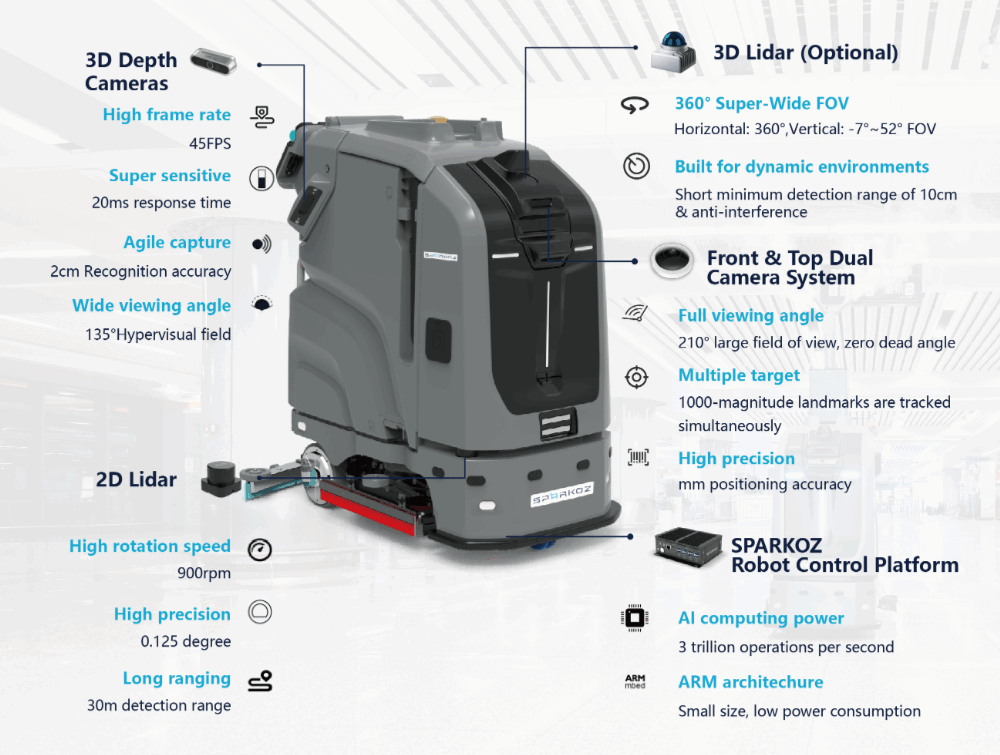

A common question is, "how autonomous scrubbers navigate" such complex and dynamic environments? The answer lies in a fusion of advanced sensors and intelligent AI, often referred to as a "sensor matrix".

Unlike a simple machine that just bounces off walls, a professional autonomous floor scrubber builds a comprehensive understanding of its surroundings. The process begins with a simple, one-time deployment. During this phase, the robot is guided through the facility to create a highly detailed digital map. This map becomes its digital blueprint for every future task.

To see and react to its environment in real-time, the robot uses a multi-layered sensor system:

● LiDAR and Vision Fusion: High-speed LiDAR (Light Detection and Ranging) scanners create a 360-degree map of structural elements, while self-developed vision fusion algorithms help the robot pinpoint its exact location.

● 3D Depth Cameras: Advanced TOF (Time-of-Flight) cameras provide a 3D view of the path ahead, allowing the robot to detect and identify low-lying or challenging obstacles that other sensors might miss.

● Ultrasonic Radar & Safety Bumpers: A final layer of ultrasonic sensors and electronic anti-collision strips ensure that the robot can safely stop if an unexpected object or person appears directly in its path.

This intelligent system allows the robot to not only follow a planned route but to dynamically and safely navigate around temporary obstacles like pallets, carts, or people.

The Practical Benefits of Robotic Floor Cleaning

Adopting this technology moves cleaning from a manual chore to a strategic, data-driven operation. The benefits of robotic floor cleaning are seen immediately in three core areas: efficiency, consistency, and safety.

Efficiency That Works Around the Clock

An autonomous floor scrubber is built for endurance. With large-capacity water tanks and long-life batteries, machines like the Sparkoz TN70 can clean for hours on a single charge.

The most critical "in action" feature is "breakpoint continuation". If the robot runs low on power or water, it doesn't just stop. It will automatically pause its task, return to its charging pile or workstation, and once replenished, navigate back to the exact spot it left off to resume the job. This ensures a 100% complete-to-plan clean, every time, without manual intervention.

Consistency and Verifiable Proof

Manual cleaning quality can vary from shift to shift. A robot executes its programmed path with the same precision every single time, including difficult-to-clean areas like edges, which it can clean with remarkable proximity.

Furthermore, this technology introduces accountability through data-based management. Facility managers are no longer just guessing if a job was done. They can remotely view detailed mission reports that show:

● Coverage Ratio: Exactly what percentage of the planned area was cleaned.

● Actual Clean Area: The total square meters/feet scrubbed.

● Work Efficiency: The cleaning rate achieved during the task.

This visualized data provides verifiable proof of cleanliness, essential for health and safety compliance in industries like healthcare, food service, and education.

A Safer Workplace and Smarter Labor

Workplace safety is paramount. Wet floors from manual mopping are a leading cause of slip-and-fall accidents. Automated scrubbers use a powerful integrated squeegee system that leaves floors perfectly dry almost immediately, drastically reducing this liability.

This automation also allows for intelligent labor optimization. Instead of spending hours on the repetitive, physically demanding task of floor scrubbing, human staff can be "upskilled." They can focus on high-value, detailed tasks that robots can't do, such as high-touch surface disinfection, complex maintenance, or customer service.

The True Future of Commercial Cleaning

The future of commercial cleaning is not about replacing people; it's about augmenting them with intelligent tools. Modern autonomous scrubbers are designed to be incredibly user-friendly. The entire complex process of deployment and task creation is simplified into a clear workflow: create a map, plan a mission, and then execute. For the daily cleaning staff, starting a shift's worth of cleaning can be as simple as a "one-click task execution".

This flexibility extends to the cleaning itself. In large, open areas like a retail superstore lobby, the robot can use an "Area Coverage" mode, automatically planning the most efficient path. In narrow, complex aisles, operators can use "Route Cleaning" mode, where they push the robot on the perfect path once, and the robot memorizes and repeats it perfectly forever.

In conclusion, autonomous floor scrubbers are no longer a futuristic promise. They are "in action" today, proving that a cleaner, safer, and more efficient facility is possible. By handling the heavy, repetitive work with intelligent precision, they provide managers with the data they need to prove compliance and free up human teams to create a truly pristine environment.

To see this technology in action, learn more about the capabilities of the Sparkoz TN70 Autonomous Floor Scrubber.